Supply Chain Policy

F&X Electro-materials Limited endeavors to be a world class supplier of tantalum and niobium products to its customers. This means not only that our customers should always get good value with a high quality product that meets their needs, but also products that have been ethically produced in a sustainable way. F&X Electro-Material Limited has been audited by a third-party auditor and certified by EICC (it has become RMI) as Conflict-Free Smelter, CFS (it has become RMAP) each year for fourteen consecutive years since the year of 2011.

F&X Electro-materials Limited is committed to follow laws, rules and regulations, respecting human rights, treating customers, suppliers, and employees honestly and fairly, and protecting the environment. We also expect all the members of our supply chain to respect these values.

As an ethical company, and a responsible member of the TIC and iTSCi, F&X Electro-materials Limited has Supply Chain Policy to avoid using the following four high-risk minerals.

1. While sourcing from, or operating in, conflict-affected and high-risk areas, we will neither tolerate nor by any means profit from, contribute to, assist with or facilitate the commission by any party of :

⑴ any forms of torture, cruel, inhuman and degrading treatment.

⑵ any forms of forced or compulsory labour.

⑶ the worst forms of child labour.

⑷ other gross human rights violations of international humanitarian law, crimes against humanity or genocide.

⑸ other serious violations of international humanitarian law.

We will immediately suspend or discontinue engagement with upstream suppliers where we identify a above reasonable risk that they are sourcing from, or linked to, any party committing serious abuses.

2. Direct or indirect support to non-state armed group.

We will not tolerate any direct or indirect support to non-state armed group through the extraction, transport, trade, handling or export of minerals, which includes,

⑴ illegally control mine sites or otherwise control transportation routes, points where minerals are traded and upstream actors in the supply chain.

⑵ illegal tax or extort money at points of access to mine sites along transportation routes or at points where minerals are traded

⑶ illegal tax or extort intermediaries, export companies or international traders

We will immediately suspend or discontinue engagement with upstream suppliers where we identify a reasonable risk that they are sourcing from, or linked to, any party providing direct or indirect support to non-state armed groups

3. Direct or indirect support to public or private security forces

We agree to eliminate direct or indirect to support to public or private security forces who illegal control mine sites, transportation routes and upstream actors in the supply chain, illegally tax or extort money at point of access to mine sites, along transportation routes or at points where minerals are traded or illegally tax or extort intermediaries, export companies or international traders. We recognize that the role of public or private security forces at the mine sites and/or surrounding areas and/or along transportation routes should be solely to maintain the rule of law, including safeguarding human rights, providing security to mine workers, equipment and facilities, and protecting the mine sit or transportation routes from interference with legitimate extraction and trade.

If we identify a reasonable risk exists, we will immediately devise, adopt and implement a rick management plan with upstream suppliers and other stakeholders to prevent or mitigate the risk of direct or indirect support to public or private security forces. In case failed attempts at mitigation, we will suspend or discontinue engagement with upstream suppliers.

4. Regarding bribery and fraudulent misrepresentation of the origin of minerals, money laundering, payment of taxes, fees and royalties due to governments.

We will not offer, promise, give or demand any bribes, and we will resist the solicitation of bribes to conceal or disguise the origin of minerals, to misrepresent taxes, fees and royalties paid to governments for the purpose of mineral extraction, trade, handling, transport and export. We will support efforts, or take steps, to contribute to the effective elimination of money laundering.

We commit to engage with suppliers, international organizations, civil society and affected third parties, as appropriate, to improve and track performance with a view to preventing or mitigating risks of adverse impacts through measurable steps taken in reasonable timescales. In case failed attempts at mitigation, we will suspend or discontinue engagement with upstream suppliers.

For purchases identified as CAHRAs, transactions will not be conducted without an upstream mechanism recognized by RMI.

If you have any further questions/complaints, please don't hesitate to contact us.

Contact Person: Ms Zhao

E-mail address: sales@fxelectro.com

Effective Date: 06 January 2025

Responsible for mineral supply chain complaint process

1. Purpose

F&X Electro-Materials LTD., realize that if we engaged in mining, trading, processing, export in the area by conflict and high-risk areas, risk of major negative impact can be formed, and realize that we have the duty to respect human rights, fueling conflict, no negative impacts on environment and social obligations, we are committed to adopt and widely implant responsible mineral supply chain policy affected in conflict and high-risk areas, and be included in the contract with the suppliers to sign and agreement. This policy provides a basic reference for the whole supply chain of mineral resources, conflict-sensitive procurement activities and suppliers' risk awareness. We commit to abide by the relevant United Nations resolutions, to abide by the domestic laws applicable to their implementation, and to refrain from engaging in any action that would help or facilitate the conflict.

To this end, the company has established a responsible mineral supply chain complaint process, and opened a complaint channel to the society, including telephone number, responsible person, in order to be willing to accept the supervision of all sectors of society.

Complaints are an important part of the company's risk assessment for the supply chain, which can help the company effectively identify risks, evaluate and reduce the risks that may form significant negative impacts on ore mining, trading, processing and export. This procedure is applicable to all tantalum raw material sources of our company.

2. Basis

《Responsible Mineral Examination Process - Tin and Tantalum Examination Standards》

《Responsible Mineral Management Procedure of F&X Electro-Materials Ltd.》

《Responsible Mineral Supply Chain Policy of F&X Electro-Materials Ltd.》

3. Scope of appeal, requirements and measures process

3.1 Scope

Applicable to the company's responsible mineral management procedures involved in the appeal and processing work.

3.2 responsibilities

The responsible mineral management team of the company is responsible for the handling of the appeal and the collection, processing and distribution of the appeal information. The management Team determines the responsible department according to the complaint content and distributes it to the relevant responsible department; The relevant responsible departments shall analyze and investigate the complaint contents, formulate corrective and preventive measures and submit them to the General Manager; The company's responsible minerals management team is responsible for tracking the outcome of the complaint.

3.3 Process

3.3.1 Receive information, inquiries and complaints from interested parties regarding concerns relating to mining, trade, processing and export conditions in the responsible mineral supply chain. Collection of appeal information The contact person to receive complaints, telephone number and email address are as follows:

Tel: +86-750-6436998 E-mail: sales@fxelectro.com.

3.3.2 Content of appeal

When a relevant party have a complaint to the company's supply chain management, the complaint shall include the following contents:

A. Include the name and contact information of the complainant, signed by the responsible person of the complainant.

B. Specify the matters to which the complaint is filed and the reasons.

C. Attach relevant written evidence.

D. Specify the steps taken to resolve the problem prior to solve the complaint.

3.3.3 Classification of complaint.

The Company shall classify and identify the complaint information received, and the complaint information is divided into general information, special and important complaint information and non-admissible information.

A. General information: relevant parties' consultation on responsible mineral supply chain management of the company, questionnaire survey of suppliers, etc.

B. Special or important complaint information, including:

1、management do not meet the requirements of the RMAP information.

2、mineral to the company with the purchasing identification of high-risk areas of the company information, such as find any related early warning signal that any products in the supply chain involved in the

3、mineral procurement does not comply with the company's supply chain policy information.

C. Information not accepted:

1、 trivial, malicious, unreasonable or suspected in order to obtain the competitive advantage of complaints.

2、no convincing objective evidence to support the vote.

D、Anonymous complaints.

With regard to anonymous complaints, F&X handles them in the following 6 steps:

1. Receiving complaints (receives anonymous complaints through a variety of channels, such as telephone, mailbox, website, letter, etc., to ensure the smooth flow of complaint channels).

2. Screening (make a preliminary judgment on the anonymous complaints received to determine whether they are related to the company's tantalum raw material purchase procurement compliance).

3. Registration and filing (detailed registration of anonymous complaints, recording key information such as the time, content, and objects involved in the complaint, and establishing a complaint file for follow-up processing).

4. Investigation (the general manager will lead an investigation team to investigate the relevant complaints, and the business department will collect relevant evidence, and take confidentiality measures for the whistleblowers and information).

5. Handling (if the content of the complaint is true, it will be handled in accordance with relevant laws, regulations and requirements, if the situation is not true, note the situation and file it).

6. Feedback (F&X will inform RMI of the relevant information and results through the company's website and email).

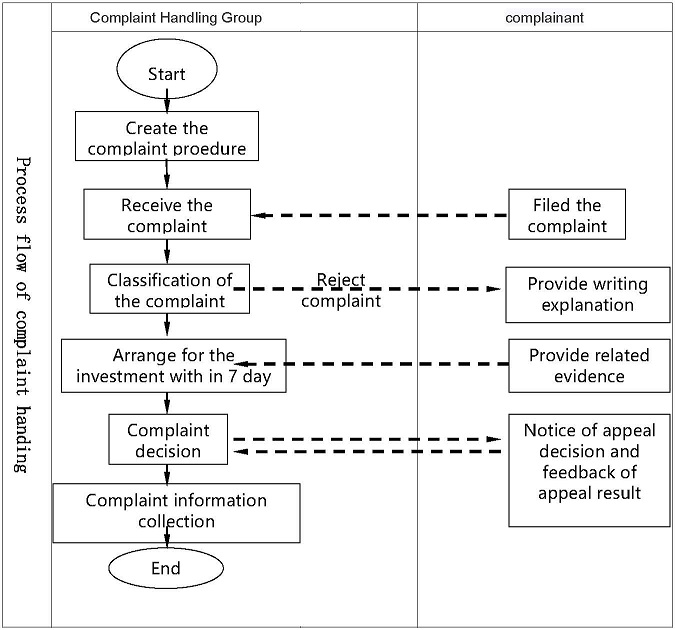

3.3.4 Process of complaints handling

The Complaint Handling Group shall confirm receipt of the appeal within 7 working days after receiving the appeal, and fill in the

For special important appeal information, the appeal handling team shall investigate, review and make a judgment on the appeal or complaint within 7 working days after the decision to accept the appeal. The processing team should make every effort to meet the deadline, but additional time may be required in exceptional circumstances. The Complaint Handling Group shall take reasonable measures, including one time or several times of meetings, to reach a reasonable decision. Examples of such measures include consultation with experts, requests for additional information from the complainant, and the non-cooperation of the complainant may be considered the reason for the termination of the procedure. The Complaint Handling Group shall decide by consensus whether to terminate the appeal proceedings. The appeal decision shall be communicated in writing to the complainant.

The Complaint decision shall include:

Complaint decision.

Complaint decision was made in how and when.

any new Suggestions

Record of Complaints: Complaints handling staff keep records of complaints received, including the following: by whom and when the complaint is filed; The type, issue or subject of the complaint and the information submitted with the complaint; Accept or reject the decision.

4. Attachment: Flowchart of Appeal Handling

F&X Supply Chain Due Diligence Report for 2024

1. Company Information

F&X Electro-Materials Limited (F&X) was established in 1999.The company’s CID number is CID000460. F&X is a smelting facility, located at YaXi Industrial Development Zone, Xinhui, Jiangmen, Guangdong, China, Postcode is 529152. The smelter is processing Tantalum and Niobium.

After more than 20 years of development and experience, F&X has become one of the world's leading manufacturers of capacitor-grade tantalum powder with continuously improved product quality and stability. F&X is a member of Tantalum-Niobium International Study Center (TIC) and a full member of iTSCi. F&X complies with laws and regulations of the People's Republic of China, all national laws, and pays all relevant taxes. F&X complies with existing legal agreements for financing, agreements with contractors and suppliers, and is fully aware of standards regarding due diligence, human rights, social responsibilities and environmental protection.

2. Summary of RMAP audit:

As a responsible company, F&X has been supporting and participating in RMI auditing. Since 2011, F&X has passed the EICC (now RMI) audit for 14 consecutive years and has a good audit record. F&X has undergone a RMAP assessment on 15th March 2024. The assessment period was from 31 January 2023 to 29 February 2024. The assessment was valid for one year. The next audit is due in March 2025, the assessment was conducted by a Responsible Sourcing Third-Party Audit Firm. The assessment summary report is public and available at: www.fxelectro.com

3. Supply Chain Policy:

F&X has fully complied with the OECD's due diligence guidelines on responsible mineral supply chains from conflict-affected and high-risk areas. In accordance with the guidelines and requirements to avoid the use of conflict minerals, which directly or indirectly finance or benefit armed groups and/or involve other serious human right abuses in high-risk and conflict-affected regions, the company has developed a supply chain policy. This policy is published at: www.fxelectro.com. According to the OECD guidelines, we have various management procedures based on different risk levels to ensure that we comply with the requirements of the five-step framework of the OECD guidelines. F&X has established a special Management Team. This team is under the leadership of the managing director and the team includes the purchasing department manager, the head of production technology department, the head of document control, the head of Ta/Nb raw material, the general manager, the quality control manager, inspection personnel, and other managers or lead personnel as required.

4. Management system:

F&X has established a complete supply chain management system with procedures to ensure that F&X has not purchased and used conflict materials from conflict-affected areas, to prevent any conflict materials or unknown materials from entering the supply chain, and to prevent mineral mining and trade from becoming sources of conflict, human rights violations and insecurity. In March 2020, with the revision of RMAP, we reviewed and revised all internal control procedures and documents to make sure that the procedures for purchasing, production, and sales meet the latest requirements. F&X has a supply chain policy and has established internal due diligence procedures in the following areas:

The managing director of F&X is responsible for supervising the formulation and implementation of the due diligence and risk management procedures.

The manager appointed to be responsible for Supply Chain Compliance is responsible for coordinating the work of relevant departments (including the business department, quality control department, production technology department and other related departments) to ensure that each department performs due diligence and reports any potential risk.

F&X has been conducting due diligence management training for all relevant departments every year based on due diligence requirements. If there is any updated information from due diligence investigations or requirements, F&X carries out additional training as needed.

4.1 Internal control system

4.1.1 F&X has updated the due diligence management system in line with OECD guidelines and RMAP.

4.1.2 F&X has updated the latest version supply chain compliance policies and procurement requirements and informed all approved suppliers.

4.1.3 F&X's published their transparent procurement policy: 1) The responsible mineral supply chain policy was published on the F&X website, so that every supplier has a clear understanding of our procurement policy. 2) The annual due diligence report was published on the F&X website, so that everyone can understand our measures and performance in responsible mineral procurement practices. 3) F&X has announced the tantalum raw material procurement statement to all suppliers. This statement included the F&X tantalum raw material procurement policy and requirements, and provided a complaint channel. At the same time, all suppliers were required to make corresponding commitments. 4) F&X has issued the Responsible Mineral Management Procedures to all departments within the company. Every employee is aware of it and can follow the procedures.

4.1.4 F&X raw material procurement control procedures: The company has formulated and executed Responsible Mineral Management Procedures, Responsible Minerals (Tantalum Raw Materials) Purchasing and Application Specifications, Inspection Tantalum-containing Raw Materials Process in importation stage, Inventory Accounting Operation Guide, Internal Numbering Rules for Tantalum and Niobium Raw Materials, Records Management Procedures, Product Identification and Traceability Management Procedures, Responsible Mineral Supply Chain Risk Identification Procedures, Responsible Mineral Supply Chain Complaint Information Processing, Due diligence plan and risk control process. These ten control procedures prevent any "conflict materials" and unknown materials from entering F&X's supply chain.

4.1.5 Tracking processing of traceable raw material: F&X implements Product Identification and Traceability Management Procedures, which guarantees the traceability and control of all tantalum raw materials in the process of using.

4.1.6 Compliance with international standards for transportation: F&X strictly follows the regulations on the transportation of hazardous substances (including 7 types of substances), and has established and implemented a Radiation Safety Management System.

4.1.7 Conduct due diligence on suppliers and maintain: F&X conducts due diligence and audits raw material suppliers every year in accordance with the OECD guidelines and the audit requirements of the Responsible Minerals Initiative. This audit reviews the legality, quality assurance level and compliance of the suppliers and is used as evidence for accepting or disqualifying the supplier. So far, no discrepancy has been found.

4.1.8 Comprehensive Communication Channels:

4.1.8.1 F&X conducts due diligence reviews on all suppliers and promotes the requirements of "OECD Due Diligence Guidelines for the Supply Chain of Responsible Minerals in Conflict-affected Areas and High-risk Areas", RMAP assessment standards, transparency, and responsible supply chains. F&X also reminds and urges upstream raw material suppliers to operate in compliance with laws and regulations, and to not collect any "conflict raw materials" or unknown raw materials. The special terms for "Responsible Minerals" are listed in all suppliers’ contracts.

4.1.8.2 F&X actively participates international conferences and trainings organized by international organizations, such as TIC, iTSCi, RMI, etc. These programs help to understand the requirements of "OECD Due Diligence Guidelines for Responsible Mineral Supply Chains in Conflict-affected Areas and High-risk Areas", RMI audit standards, and responsible tantalum supply chain transparency. In order to understand the production and operation of each mine in a timely manner, F&X communicates with iTSCi regularly, and pays close attention to iTSCi incident reports, monthly production evaluations, monthly regional status/evaluation reports etc.

4.1.9 In order to ensure due diligence in the supply chain F&X has frequent communication with downstream customers and follows the requirements of the Responsible Business Alliance (RBA) to provide Conflict Minerals Report (CMRT) information to downstream customers.

4.1.10 F&X publically promotes, on it’s website, the “OECD Due Diligence Guidelines for Responsible Mineral Supply Chains in Conflict-affected Areas and High-risk Areas”, the latest requirements of the Responsible Business Alliance on the verification standards of tantalum supply chains, and the transparency of responsible mineral supply chains. F&X supports the principles and standards of the Extractive Industries Transparency Initiative (EITI). No matter if the suppliers are from an EITI implementing country or non-implementing country, F&X keeps effectively communicating with them about EITI and gets back their confirmation.

4.1.11 F&X has established and implemented a Responsible Mineral Supply Chain Complaint Information Processing Process and opened a complaint channel to public on it’s website, including telephone numbers, person in charge, and email address, to accept supervision from public.

4.1.12 F&X is willing to share supply chain data and information with upstream and downstream customers if necessary.

4.1.13 Training employees: F&X trains employees including senior management, to help them fully understand "OECD Due Diligence Guidelines for Responsible Mineral Supply Chains in Conflict-affected Areas and High-risk Areas" and the Responsible Business Alliance's latest requirements on the verification standards for the tantalum supply chain and the requirements for responsible mineral supply chain transparency. This training gives our employees the information necessary to understand and support the principles and standards of Extractive Industry Transparency Initiative (EITI).

4.1.14 F&X strives to have legal and ethical operations, actively carries out its social responsibilities, and builds a compliant and responsible company image. F&X has always integrated the economic development and social responsibilities through the implementation of technological innovation, safe production, employee rights, environmental friendly operations and emission reduction programs.

4.2 Record retention system: F&X has established and implemented a Record Management Procedure to comprehensively preserve the records of responsible mineral procurement, usage and etc... These records are maintained as original copies and/or electronic copies, with not less than a 5 years record retention period. Records within the retention period can be reviewed upon authorization - for example, Shipment Records, Customs Clearance Records, Quality Recheck Records, Quantity Recheck Records, Political Documentation Records including iTSCi shipment number, tag.

5. Risk Identification

5.1 Supplier identification: F&X uses KYC system and KYC forms, including suppliers’ legal status and identity of owners, business scope, and origin of materials with relevant supporting documents. All suppliers have completed and returned the form to F&X. F&X ’s due diligence management and the procurement team reviewed the information. If inconsistencies, errors or incomplete information are found in the KYC form, F&X asks them to make improvement. So far, all suppliers in our qualified suppliers list, have returned the KYC forms, and nobody refused to fill out the form or correct incomplete or incorrect information.

5.2 Conflict affected and high-risk areas (CAHRA) tools and standard: F&X has identified four risk assessment tools to review supply chain risks. After reviewing the supply chain risks by four risk assessment tools, if the region is not a high-risk region, the region is suitable for low-risk source management, otherwise, it requires high-risk source management. We have recorded the countries and/or regions that identified as CAHRA, we refer to the RMI website on a timely basis to learn and update more information about CAHRA identification, to identify any warning signs, disqualification or discrepancies of suppliers or raw materials, and review raw material categories and source information.

5.3 Identify and evaluate supply chain risks: F&X has identified and organized the risks in the supply (supplier) chain, and written a report, which was approved by the managing director. Before signing a contract for each tantalum raw material procurement transaction, F&X has used the risk identification tools to identify the source of minerals and transshipment country based on the information and materials provided by the supplier and the information provided by the iTSCi/BSP, supply chain supervision system. So far, no problem has been found.

5.4 For each transaction, F&X requires suppliers to provide origin information and a full set of traceability documents, including legal transportation route, names and addresses of direct suppliers.

6. Risk management and risk reduction strategies

6.1 If there is no supply chain supervision system (such as iTSCi/BSP) for a region or if a potential supplier is identified as high-risk by F&X after evaluation, F&X will not purchase and has not purchased anything from that region or supplier.

6.2 For each transaction from a high-risk area, F&X has always used the following plan to assess its risk:

A. For each transaction from a high-risk area, F&X has been using iTSCi/BSP's "Tag&Bag" system. As a full member of iTSCi, F&X has been actively supporting iTSCi's work by joining its traceability verification on high-risk tantalum raw materials. F&X only purchased iTSCi/BSP system certified minerals, and suppliers must be iTSCi/BSP members. F&X recorded all due diligence information from iTSCi/ITRI, RMI and third-party audits. So far, no discrepancy has been found. iTSCi provides the following documents and reports: 1) Event summary report; 2) Mine survey recommendations, including a list of potential risk mines (it is recommended to conduct enhanced due diligence and risk assessment of these companies) ; 3) Country and regional monthly reports that review the general situation in the field; 4) data summary and other reports. F&X has collected and studied the documents and reports provided by iTSCi in a timely fashion.

B. In the absence of an upstream mechanism assessed or endorsed by RMI, F&X conducts additional risk-based checks (such as geographic scope restrictions on upstream project implementation locations) to assess the overall credibility and supply chain risks, including the robustness of information collection and transmission, in the context of the transaction, the transaction process, suppliers, etc.

During the period of 2023-2024 annual RMI audit, we identified all raw materials from three aspects of conflict, human rights and governance according to the risk identification and assessment tools specified in the risk identification procedure. During the current period, we did not make any purchases from CAHRAs, and all raw materials purchased were certified as compliant.

F&X ELECTRO-MATERIALS LIMITED

January 6th, 2025

Support Extractive Industries Transparency Action Plan Initiativ

It is in the common interests of resource-rich countries, extractive industry companies and the international community to support the EITI to promote transparency and strengthen accountability. As a member of the tantalum industry, F&X has made a commitment to the domestic and international communities to increase transparency, and strengthen accountability systems in public life as well as government management and business practices in order to reduce and eventually prevent conflicts related to the oil, gas and mining industries.

F&X promises to cooperate with suppliers, central and local Governments, international organizations, civil societies and affected third parties to take significant risk reduction measures to prevent or reduce risks in a reasonable certain time. In that way we can measure the progress and make improvement. If the risk reduction measurements do not work, we will temporarily suspend or terminate the cooperation with upstream suppliers.

F&X ELECTRO-MATERIALS LIMITED

January 1st,2025

What is EITI?

What the EITI does: Building trust through transparency

A country’s natural resources, such as oil, gas, metals and minerals, belong to its citizens. Extraction of these resources can lead to economic growth and social development. However, poor natural resource governance has often led to corruption and conflict. More openness and public scrutiny of how wealth from a country’s extractive sector is used and managed is necessary to ensure that natural resources benefit all.

The EITI is a global standard to promote transparent and accountable management of natural resources. It seeks to strengthen government and company systems, inform public debate and promote understanding. In more than 50 implementing countries, the EITI is supported by a coalition of government, companies, and civil society.

The information found in EITI Reports helps governments monitor and forecast revenues from their extractive sector. Countries can use this information to verify that they are receiving the amount due to them. The EITI alone does not enable such verification. EITI Reports must be comprehensible, actively promoted, publicly accessible, and contribute to public debate. Implementing countries are also required to publish “electronic data files” and are encouraged to move towards online disclosure of payments and income. More and more EITI Reports also include information on how revenues are distributed nationally, including in budgets and sovereign wealth funds, which have a vital role to play in supporting any fluctuation in the budgets and currencies of resource-rich countries.

The impact of the EITI is evident when governments decide to implement the recommendations that have emerged from EITI reporting. In some countries, EITI Reports have been a useful tool highlighting weaknesses in government systems. In other cases, the report recommendations have been aimed at addressing such weaknesses and improving sector management, thus making an important contribution to policy reform and change.

EITI standard

The Extractive Industries Transparency Initiative (EITI) is the global standard to promote the open and accountable management of oil, gas and mineral resources. At the EITI London Conference 2005, participants in the EITI adopted the implementation criteria. The EITI Standard was launched on 18 June at the Paris Global Conference.

THE EITI STANDARD 2023 download (https://eiti.org/sites/default/files/2024-04/2023%20EITI%20Standard_Parts1-2-3.pdf)

The EITI Principles

1. We share a belief that the prudent use of natural resource wealth should be an important engine for sustainable economic growth that contributes to sustainable development and poverty reduction, but if not managed properly, can create negative economic and social impacts.

2.We affirm that management of natural resource wealth for the benefit of a country’s citizens is in the domain of sovereign governments to be exercised in the interests of their national development.

3.We recognise that the benefits of resource extraction occur as revenue streams over many years and can be highly price dependent.

4.We recognise that a public understanding of government revenues and expenditure over time could help public debate and inform choice of appropriate and realistic options for sustainable development.

5.We underline the importance of transparency by governments and companies in the extractive industries and the need to enhance public financial management and accountability.

6. We recognise that achievement of greater transparency must be set in the context of respect for contracts and laws.

7.We recognise the enhanced environment for domestic and foreign direct investment that financial transparency may bring.

8.We believe in the principle and practice of accountability by government to all citizens for the stewardship of revenue streams and public expenditure.

9.We are committed to encouraging high standards of transparency and accountability in public life, government operations and in business.

10.We believe that a broadly consistent and workable approach to the disclosure of payments and revenues is required, which is simple to undertake and to use.

11.We believe that payments’ disclosure in a given country should involve all extractive industry companies operating in that country.

12. In seeking solutions, we believe that all stakeholders have important and relevant contributions to make including governments and their agencies, extractive industry companies, service companies, multilateral organisations, financial organisations, investors and non governmental organisations.

THE EITI Principles download (https://eiti.org/documents/eiti-principles)

Reference website

EITI Principles

https://eiti.org/document/eiti-principles

EITI Standard

https://eiti.org/files/documents/eiti_standard_2019_en_a4_web.pdf

OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas

Responsible Minerals Assurance Process Tin and Tantalum Standard